Low-Cost Colour Inkjet Brings High Value to Omaha Public Schools

Steve Priesman was convinced that printing more instructional materials in colour was critical to ensuring the best possible learning experience. But the in-plant he led as Omaha Public Schools (OPS) Manager of Printing and Publications Services could afford to use colour only sparingly given their aging press fleet.

Moreover, expanding use of colour was only one of the shop’s needs. Priesman’s difficult challenge was to upgrade the pressroom for greater capacity and faster turnarounds without increasing spending, and he hoped that a new generation of inkjet presses could help.

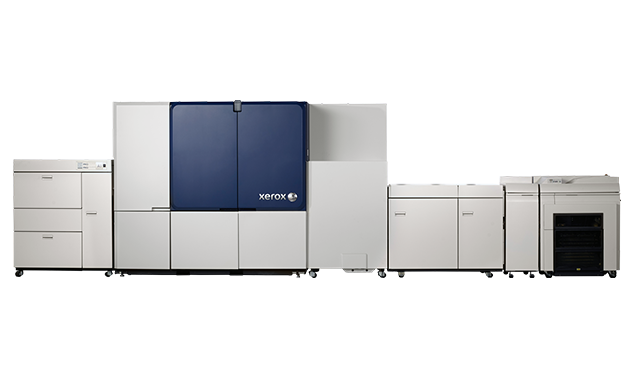

In June 2018, Priesman replaced half his presses with a Xerox® Brenva® HD Production Inkjet Press. Because its colour printing costs were about the same as traditional monochrome, colour orders exploded. That led OPS to replace its remaining equipment with a second inkjet press, the Xerox® Baltoro® HF Inkjet Press, boosting shop capacity by 60 percent in the process.

Just as their Baltoro on-boarding and training began in March 2020, the solution was tested with perhaps the most demanding job of Priesman’s career. The shop was asked to produce more than 50,000 instruction packets comprising 1.25 million double-sided sheets in just six days—work that would normally take two months. This work was critical to support the initial move toward at-home learning during the coronavirus pandemic.

OPS quickly dedicated their two Xerox Inkjet Presses to 24/7 production and, with some supplemental outsourcing, met the deadline. It was trial by fire, Priesman said, “and we’re real proud of our response.”

Now colour orders continue to grow. “I don’t think it’s possible to quantify that a colour document is X percent more effective than monochrome,” he said. “But I’m confident the improved comprehension is there.” Add in the in-plant’s faster turnarounds and 60 percent boost in capacity and, Priesman said, “That’s a winning combination.”

Think you can’t achieve offset-like quality with inkjet?

See how print professionals fared when they took the Print IQ challenge to tell our offset and inkjet samples apart

Read Full Case Study

Stampante a getto d’inchiostro Xerox® Baltoro® HF

Prestazioni ed economia trasformative fornite attraverso un'innovazione ispirata.

Articoli correlati

La tipografia britannica produce progetti ad alto valore e al contempo riduce l'impatto ambientale

Rapidity guadagna in efficienza e versatilità con le stampanti di produzione Xerox® Iridesse®.

Migliore coinvolgimento degli studenti

Scopri come l’utilizzo della stampante a getto d’inchiostro Xerox® Baltoro® HF aiuta i servizi didattici DCMO BOCES a offrire contenuti più coinvolgenti e a risparmiare notevolmente.

Solving Print's Pain Points

Explore the latest trends and solutions in print operations with Printweek’s special supplement, sponsored by Xerox. Gain insights into digital transformation, efficiency, and sustainability for your print business.

Getting Started with Xerox® FreeFlow® Core

Join our Xerox virtual webinar to help streamline your pre-press workflow and say goodbye to touchpoints and bottlenecks.

Power Up Your Production Print Profitability

Our infographic provides an at-a-glance look at the latest industry intelligence to help put your production print operation on the path to profit and growth. Download it now.

How Print Service Providers Can Drive Profitability

Download our checklist to help you stay ahead of industry headwinds and be more profitable while managing the shift toward shorter, faster turnaround jobs.